Increasing part quality and time efficiency via Autonomous Optimization

New SIGMASOFT® technology brings injection molding simulation to the next step

In 2018 SIGMA Engineering exhibits for the first time at Plast show with their own booth. During the show it presents its SIGMASOFT® Virtual Molding technology and the new Autonomous Optimization to the Italian market. The Autonomous Optimization brings out a completely new simulation approach to optimize plastic and rubber applications.

At Plast 2018, taking place between May 29th and June 1st,2018, in Milan, Italy, SIGMA Engineering GbmH, Germany, showcases its SIGMASOFT® Virtual Molding technology for plastic and rubber applications in hall 11 at booth A167. SIGMA is exhibiting for the first time with its own booth, thus deepening its commitment to the Italian market and strengthening the relationship with local customers.

During the show Italian molders have the opportunity to learn first-hand about the capabilities of SIGMASOFT® Virtual Molding and the Autonomous Optimization technology and their benefits for the daily work of injection molders. SIGMASOFT® Virtual Molding converts the computer into a virtual injection molding machine, on which the part, mold and process can be developed and evaluated without wasting resources. Additionally, the real injection machine is available for production and not occupied with trial-and-error.

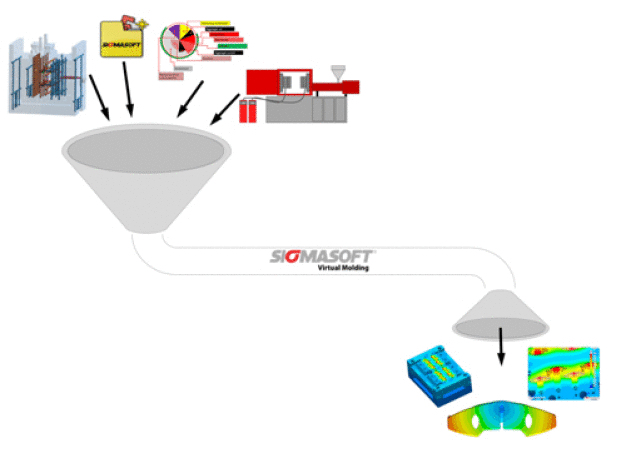

In a present where molding applications need to be up to very high standards regarding part quality as well as time and cost efficiency, SIGMASOFT® Virtual Molding can be the ideal assistant in finding the optimal solution for a specific problem. Until now, the simulated injection molding partly consisted of trial-and-error, just as the process in reality does as well. The user needed to provide material and geometry data and configure the process data to get a result for this one defined input combination (Fig. 1). Especially if the optimal solution consists of an unusual parameter combination, it may be unlikely or very time-consuming to find this set-up via trial-and-error.

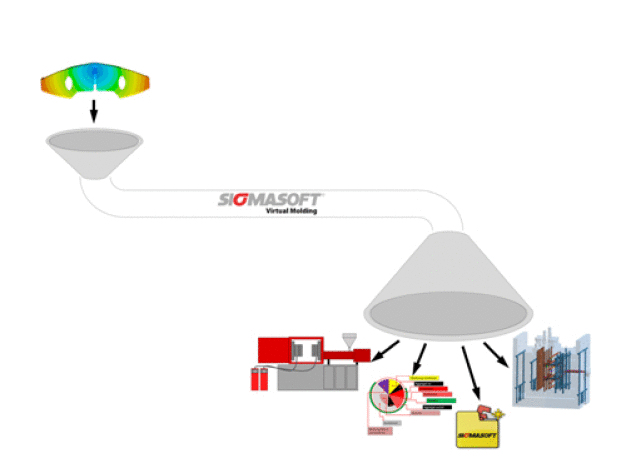

This is where the new Autonomous Optimization comes into play. Instead of testing different approaches, the definition of a certain objective, e.g. minimal warpage, and the possible variances of material, geometry and process variables forms a sufficient basis for the software to find the ideal parameters leading directly to the desired goal. Therefore, this new technology completely reverses the traditional approach by starting from the former goal (Fig. 2), is able to autonomously calculate the optimal process set-up and the user can also determine the process window for production after just one calculation run. This does not only save much effort and time but also simplifies the discovery of innovative approaches which can greatly increase the part quality.

SIGMA Engineering GmbH

52072 Aachen

Germany