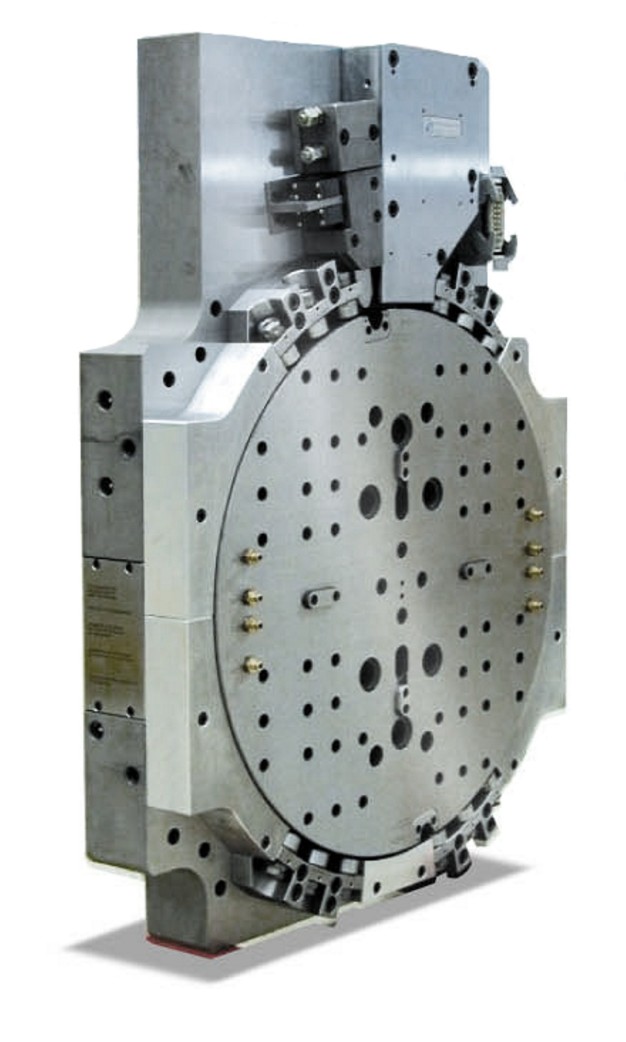

Rotation plate technology with high diameters in Bestform

Brown form sees trend for large, compact rotation plates up to 1,400 mm in diameter the K2010 focuses itself to brown form on current trends in tool technology. In the center tools are located for the medicine and multi-component equipment. Brown form presents a 32+32-fach-Drehwerkzeug with rotation plate. The robust and fast rotation plates of the series 540 up to the series 1400 (turning disk diameter 500 mm up to 1,360 mm) after EURO MAP are by their slim construction a highlight on the conditions of the Bahlinger. As one of the few offerers the pioneer offers rotation plates in the upper class between 900 and 1,400 mm in diameter to this MK-technology. Since 1990 brown form for this technology engages itself. Hitting a corner pool of broadcasting corporations harsh, managing director of brown form, observes for some time a trend to rotation plate tools with larger diameters: � those increasingly complex geometry or also the multi-cavity strategy requires increasingly large rotation plates. They should be fast both compactly, and. Which counts however above all in practice, is a robust and flexible rotation plate. � brown form offers for it an extensive program up to � the Titanen � under the rotation plates with 1,400 mm in diameter (turning disk diameter 1,360 mm). Pluses in the DetaiDrehteller from Bahlingen are characterised despite the high dynamic forces by high robustness. Quintessential point of the robustness is the taken off ball race, which promises high lifetime cycles. The flexibility of the construction offers numerous advantages in the everyday life enterprise to the processing plant and permits faster and more efficient solutions in the MK-technology. Connections on the face make an extremely flexible water supply possible with high cooling agent flow for short cycles. As option realizable is also a direct delivery to the tool. At rotation plates of brown form tool changes without adapters take place. This makes much snaps and efficient tool changes for the processing plant possible. The newest generation of rotation plates from the house brown form does not only stand for very fast Wendezeiten. The rotation plates of the Bahlinger build very flat: They draw by low overall heights out with the result: Shorter strokes with opening of the tool save cycle time or it remain more area for complex tools. Numerous special options round the program off. The rotation plates of the series 540 to series 1400 as basic LINE or Premium LINE offered for maximum tool tools in the range from 450 to 4,000 kg. Premium LINE � options for more FreiheitIn of the standard indexation (basic LINE) works a hydraulic motor endlessly turning in the turning angle of 180� with hydraulic bolting device in end position position. As Premium LINE offers a hydraulic motor for turning angles with 120� (3 station clocking) and 90� (4 station clocking) for additional tasks of multi-component to brown form. Available also an electrical servo actuator is inclusive SPS. In the Premium LINE cooling circuits are integrable plus air and hydraulic systems up to 6. Brown form offers turning off units also integrated for unscrewing functions and an ejector with individual ejector picture, inter+craved. Further auxiliary options on Anfrage.K2010: Brown form shows 900er-Multikavit�ten-Drehteller with TPE/PS TeilAus the medium sized assortment shows brown form a 900er-Drehteller to the K2010. The 900mm-Drehteller is equipped with the tool half of a 32+32-fach-Multikavit�tenwerkzeugs (32+32-fach SGW for Regular Head Guard). Whereupon a customer manufactures of brown form a 2K-Rasiererteil as TPE HP combination with a partial weight of 0.83 G. each. This rotation plate is suitable, after information of brown form, for machines within the closing force range from 2.500 to 2,750 kN at one Wendezeit of 1.5 seconds in continous use. Information block: Rotation plates and alternative rotations for those MehrkomponententechnikRotatori transfer VorformlingeIn of the multi-component equipment come predominantly rotating motion to the transfer of the Vorformlinge from a station to the next to the employment. The rotating motion takes place - as turn of the tool by integrated or self-sufficient rotation plates on the mobile plate or - as floor turning technology with 2 or several interface levels or - as turret plate technology (cube) with possible points of moulding on from 5 sides. While when using index plates or index crosses essentially only the cavity employments are turned, with the rotation plate technology the entire tool half is moved. The user has the choice: Self-sufficient rotation plates or integrated rotation plate rotation plates are used mostly as self-sufficient solutions for several tools. As a modular component alternatively index crosses or index plates can be integrated in the tool or as a special case into the mobile plate of the machine.

This text was translated automatically.